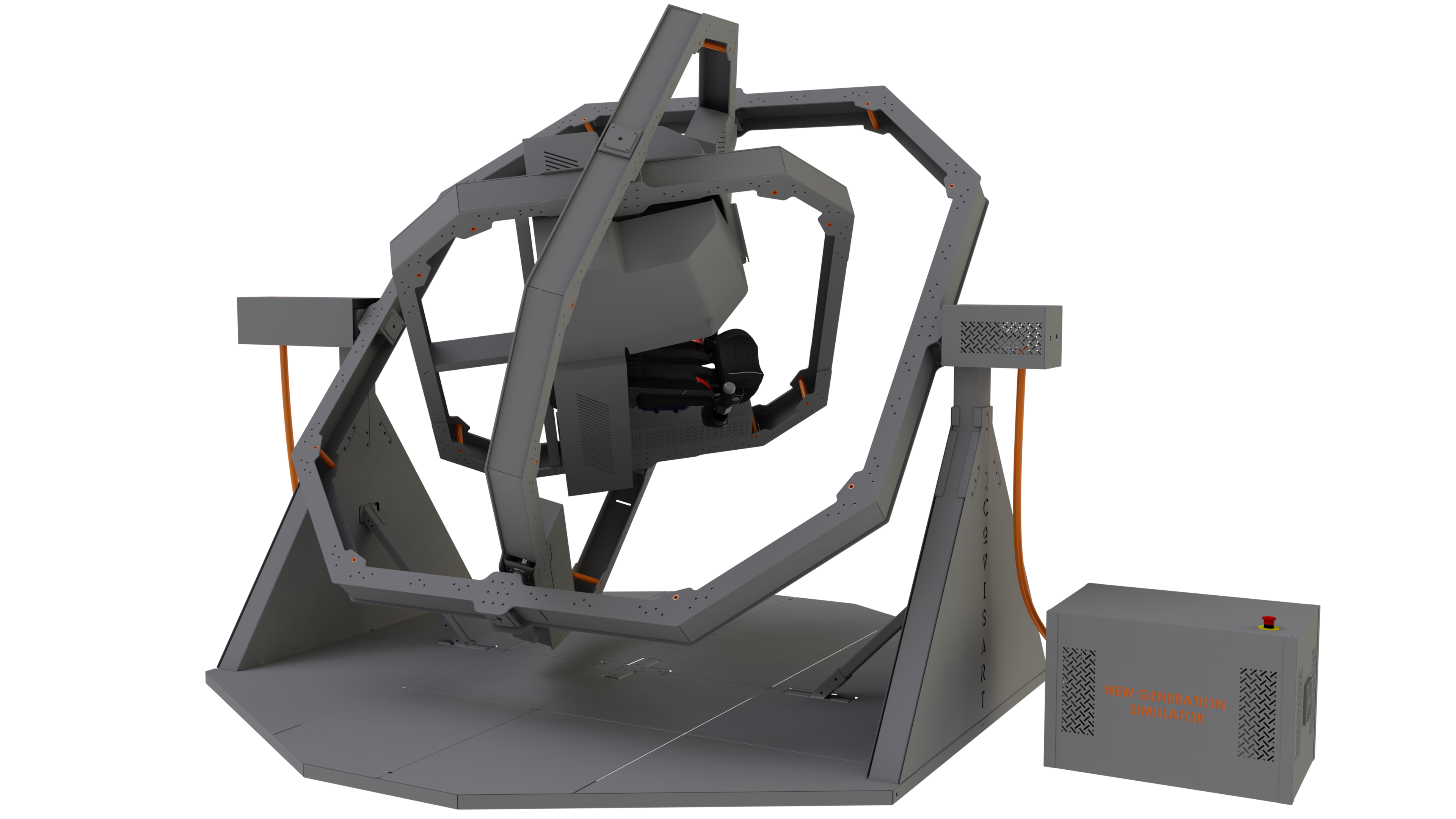

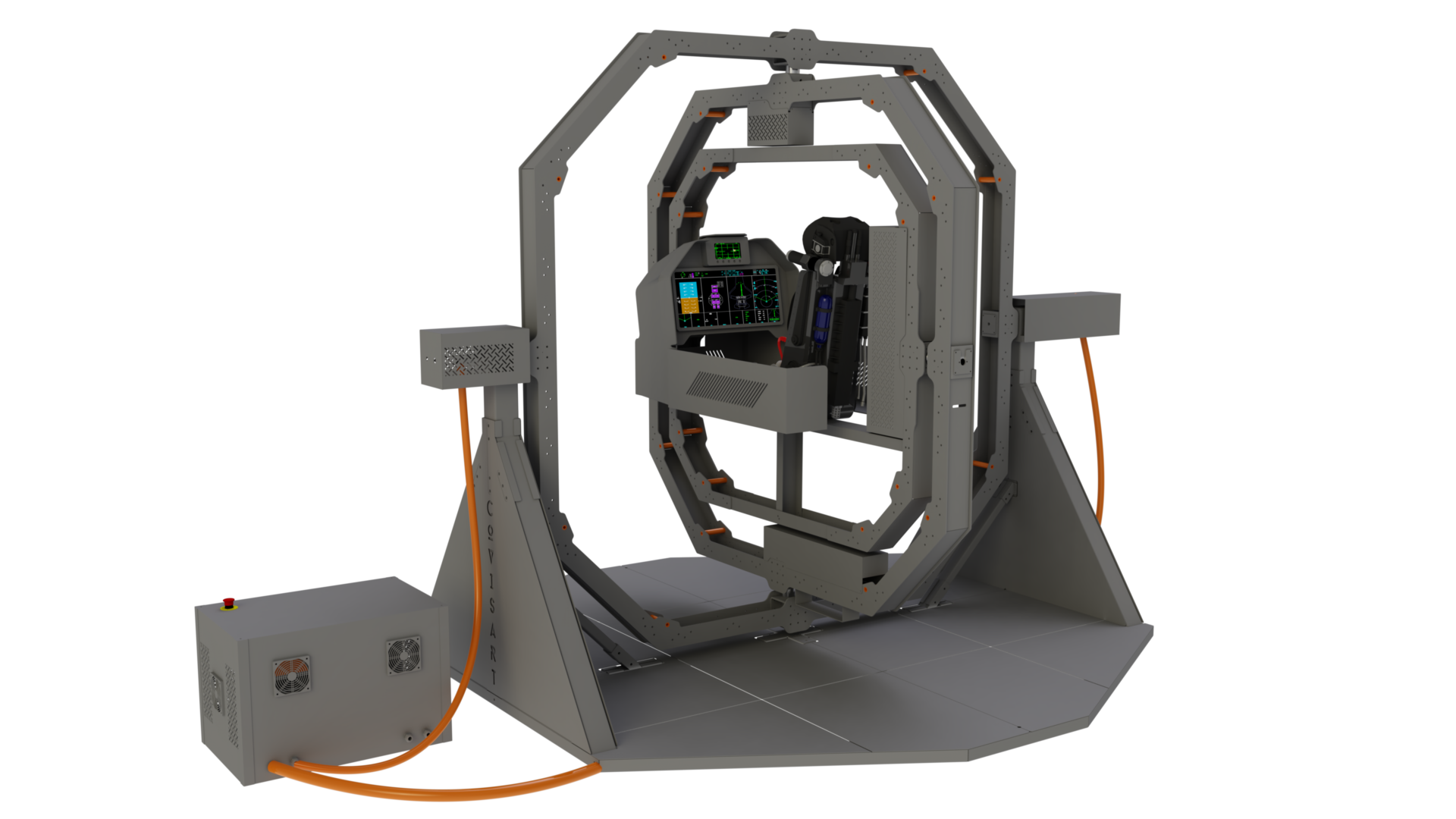

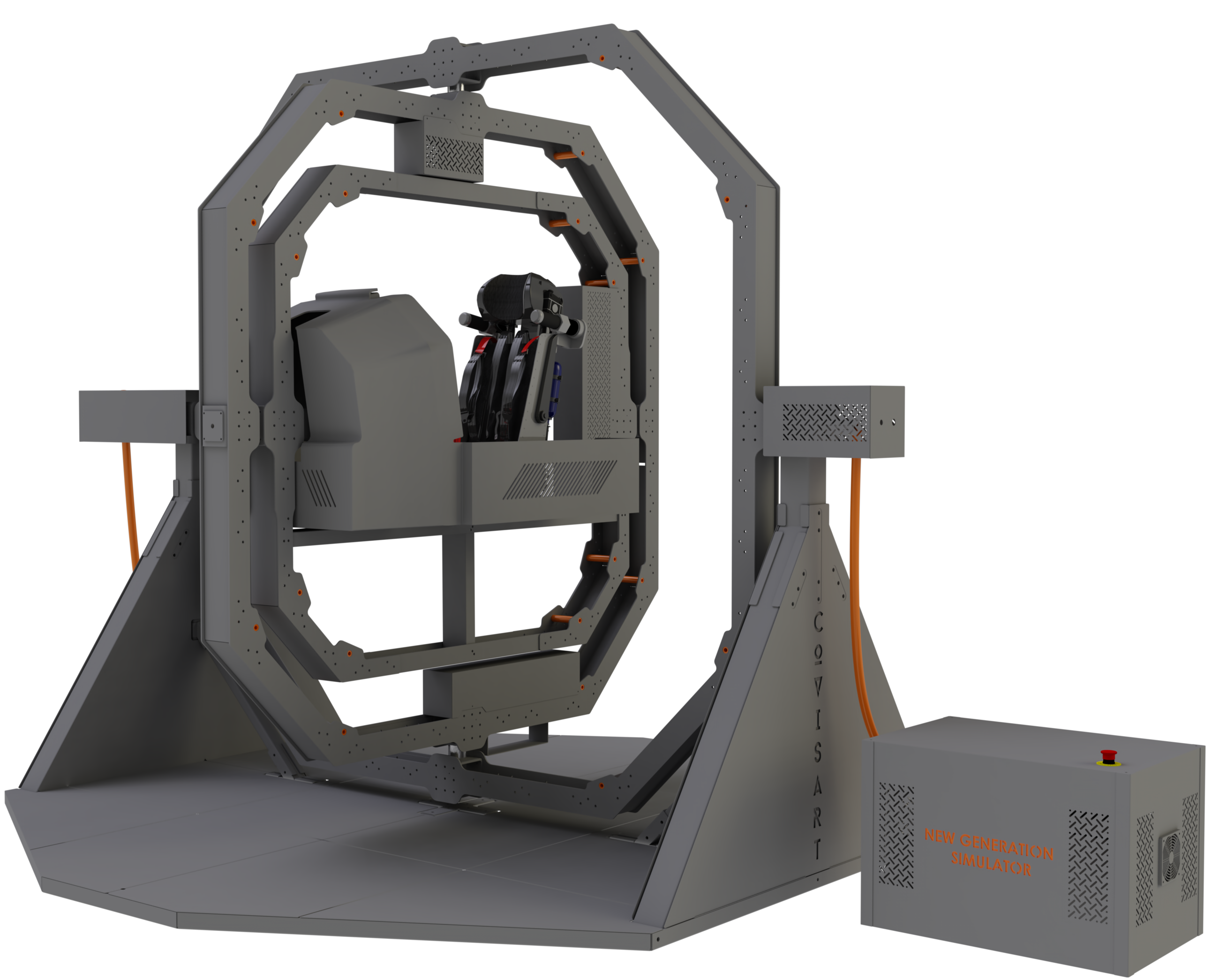

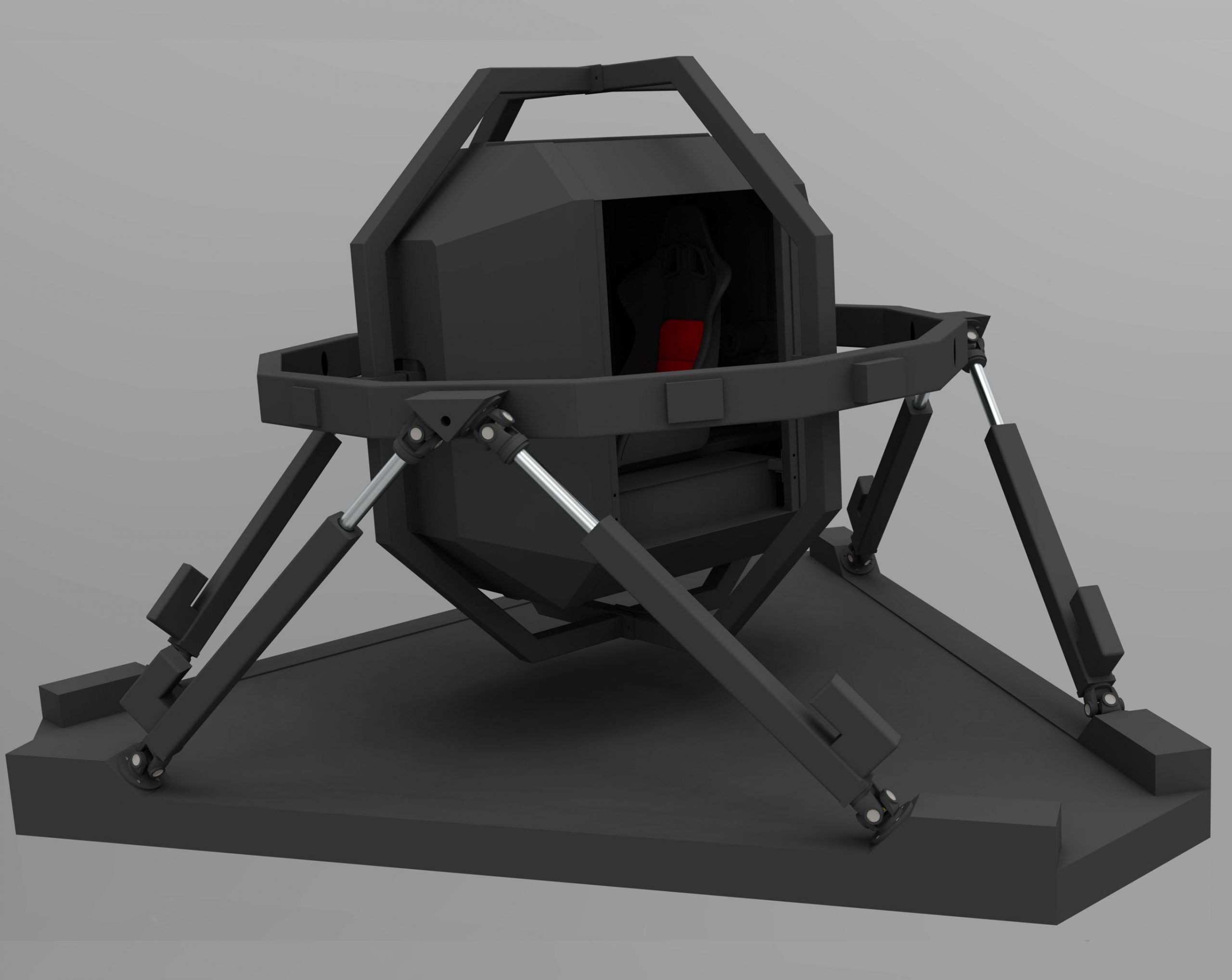

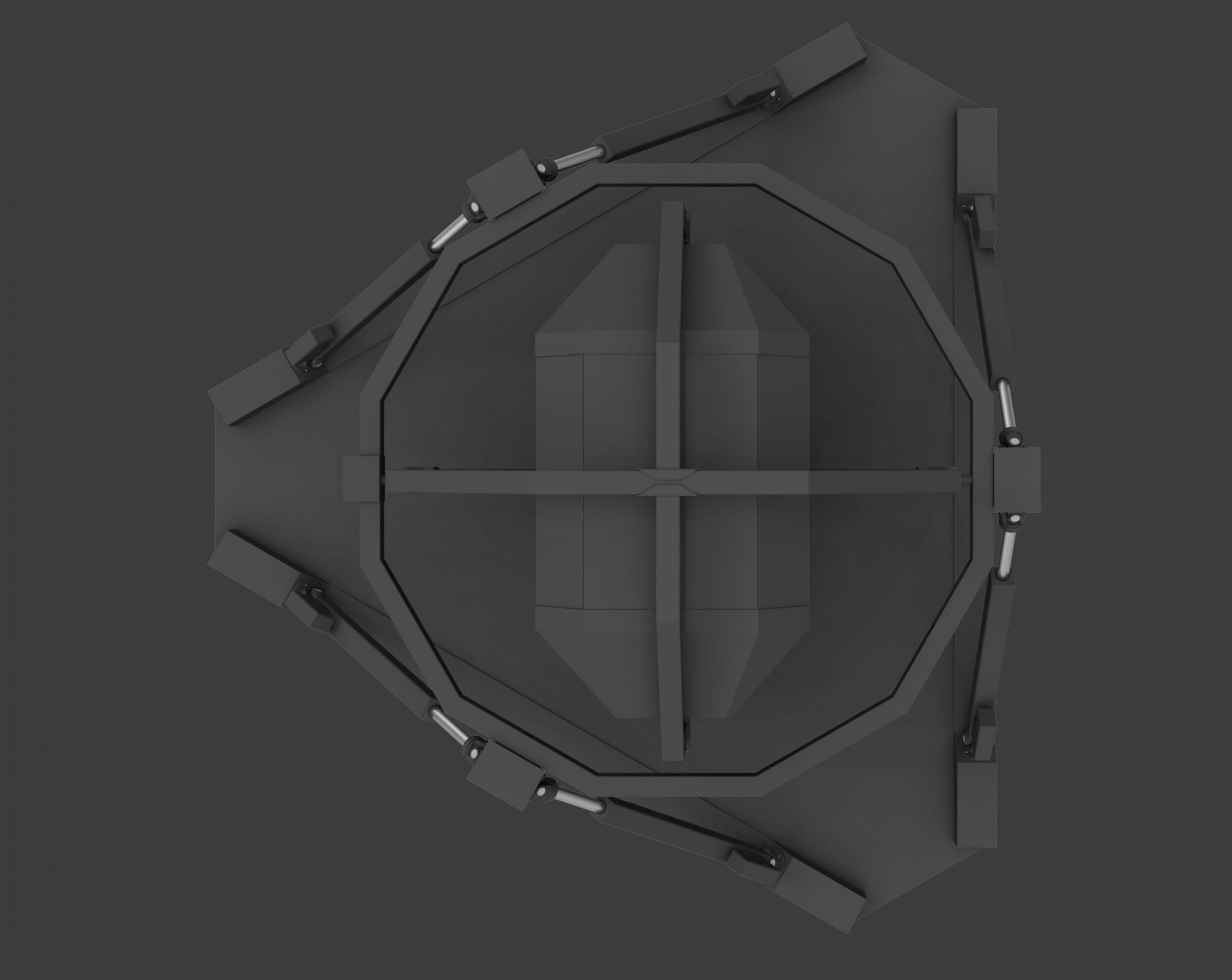

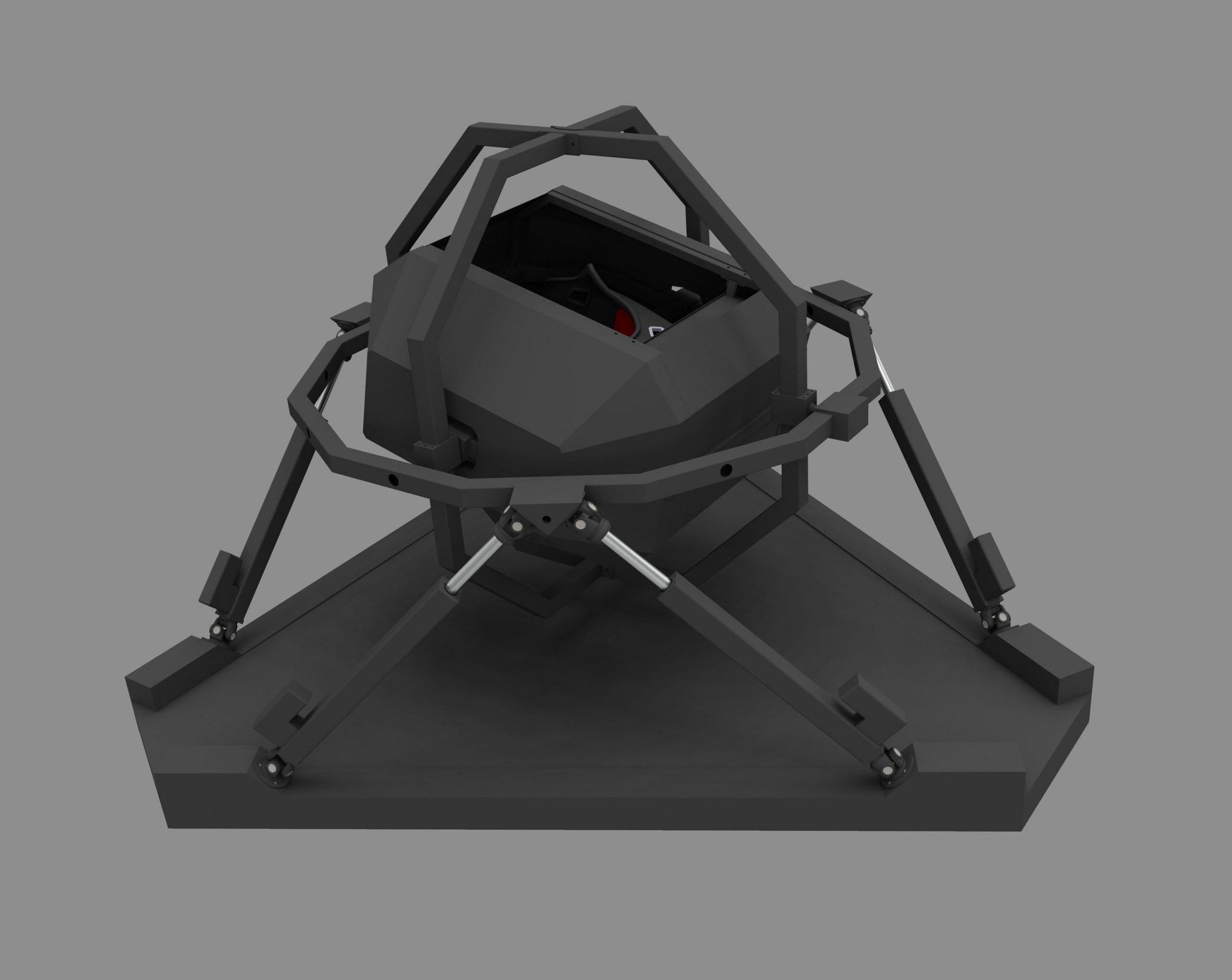

motion simulator ngs-360-3 axis simulator 360 degree simulator

In motion simulation, COVISART offers electrically driven motion systems for today’s simulation market. The NGS-360-3 is designed for today’s middle payload range in the electric driven motion systems product line: 800 kg.

NEW GENERATION SIMULATOR (NGS) aims to take on a much wider set of problems, including examining the causes of disorientation and other medical and human-factors science related.

Covisart NGS-360-3 was awarded with IFIA Best National Invention Medal by International Federation of Inventors Associations.

Full moduler design. NGS uses commons parts on many compartments. It provides short production time and increase quality of service support

Motion simulator Powered With AI

If you want to improve skills, purchase New Generation Simulator NGS-360-3

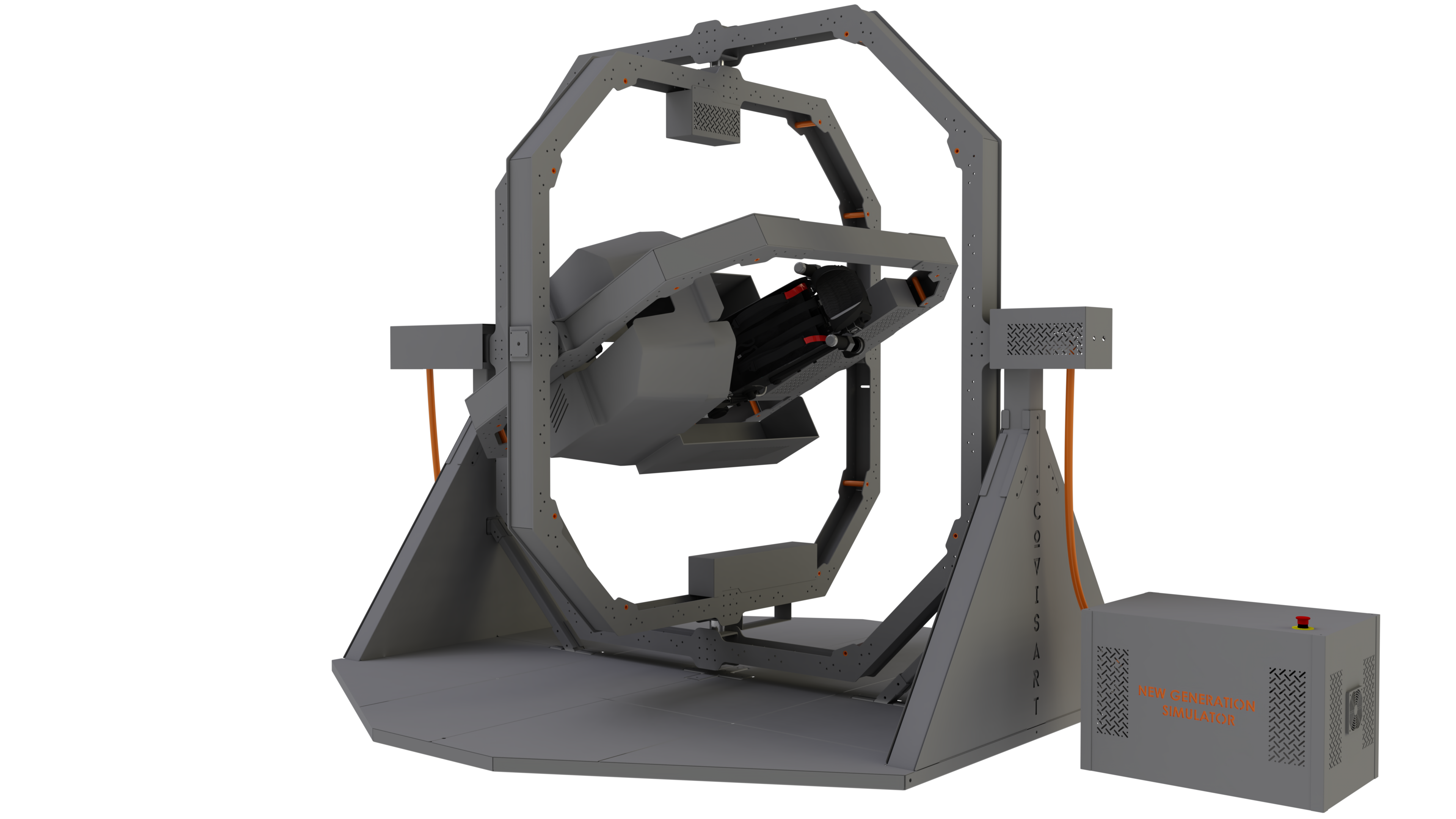

Mechanical System

The motion system, which has unlimited rotation capability in 3 axes, applies the movements of the vehicle in simulation with 1ms communication speed to the user. Developed by taking gyroscope as an example, this machine supports not only 3 axes but also multiple axes.

Safety first of all!

Mechanical and software are tested and documented.

One of the most important points of the systems used in the motors and mechanical accents are designed with utmost safety in mind, and special protection software is taking all kinds of security measures.

High Speed Communication

Thanks to the high precision and fast data processing servo motors used in the mechanical parts, it achieves 1ms communication speed. If we consider the 5ms image refresh rate of the computer screens we use today, it is possible to realize that the simulator has a faster communication power than thought.

Major Development in Education

Providing one-to-one vehicle training with low cost, the New Generation Simulator now provides a very easy and reliable visual environment.

Simulator Detail

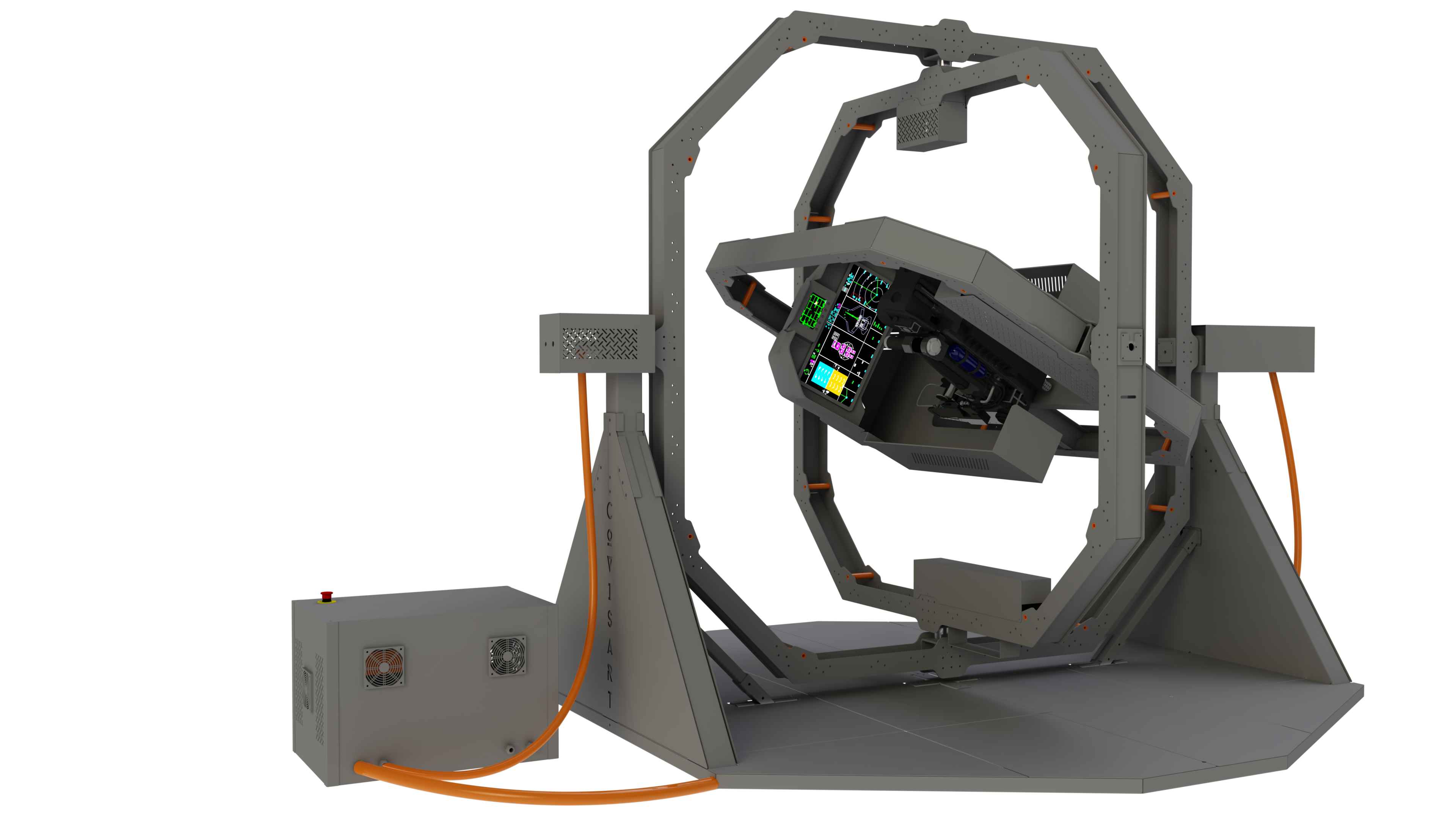

NEXT GENERATION SIMULATOR NGS-360-3 has 3 axis rotation system. Rotation axis is based NGS-360-2, speed turns on each three axis are 180 degree/s. You can find more detail about this system below. This version can simulate any vehicle(jet fighters, airplanes, helicopters, tanks and cars).

Mechanical System

The motion system, which has unlimited rotation capability in 3 axes, applies the movements of the vehicle in simulation with 1ms communication speed to the user. Developed by taking gyroscope as an example, this machine supports not only 3 axes but also multiple axes.

Safety first of all!

Mechanical and software are tested and documented.

One of the most important points of the systems used in the motors and mechanical accents are designed with utmost safety in mind, and special protection software is taking all kinds of security measures.

High Speed Communication

Thanks to the high precision and fast data processing servo motors used in the mechanical parts, it achieves 1ms communication speed. If we consider the 5ms image refresh rate of the computer screens we use today, it is possible to realize that the simulator has a faster communication power than thought.

Major Development in Education

Providing one-to-one vehicle training with low cost, the New Generation Simulator now provides a very easy and reliable visual environment.

| General performance | |

|---|---|

| Payload (without computer and other electronic stuffs, comes already installed) | 120 Kg |

| Height | 218 cm |

| Width X | 230 cm |

| Width Y | 300 cm |

| Area | 6.90 m² |

| Settled height | 0.3 m |

Angular Ranges

| Direction | Minimum | Maximum |

|---|---|---|

| Roll | – 360 deg | +360 deg |

| Pitch | – 360 deg | +360 deg |

| Yaw | – 360 deg | +360 deg |

Velocities

| Direction | Velocity(max, recommandent) | |

|---|---|---|

| Roll | +/- 225 deg/s | +/- 180deg/s |

| Pitch | +/- 210 deg/s | +/- 145deg/s |

| Yaw | +/- 225 deg/s | +/- 180deg/s |

Accelerations

The above performance figures are with the starting position ‘neutral’ and with the design payload.

| Direction | Acceleration | Onset |

|---|---|---|

| Roll | +/- 572 °/s² | +/- 300 °/s²/s |

| Pitch | +/- 370 °/s² | +/- 180°/s²/s |

| Yaw | +/- 420 °/s² | +/- 270°/s²/s |

Interfaces

- Host computer

-

- Ethernet connection

- Update rate up to 1000 Hz

- Foot-print: 2300 mm x 3000 mm

- Floor attachment: Bolted using floor anchors

Worldwide customer support:

- 24-hour service and maintenance support by Covisart’s global service organization

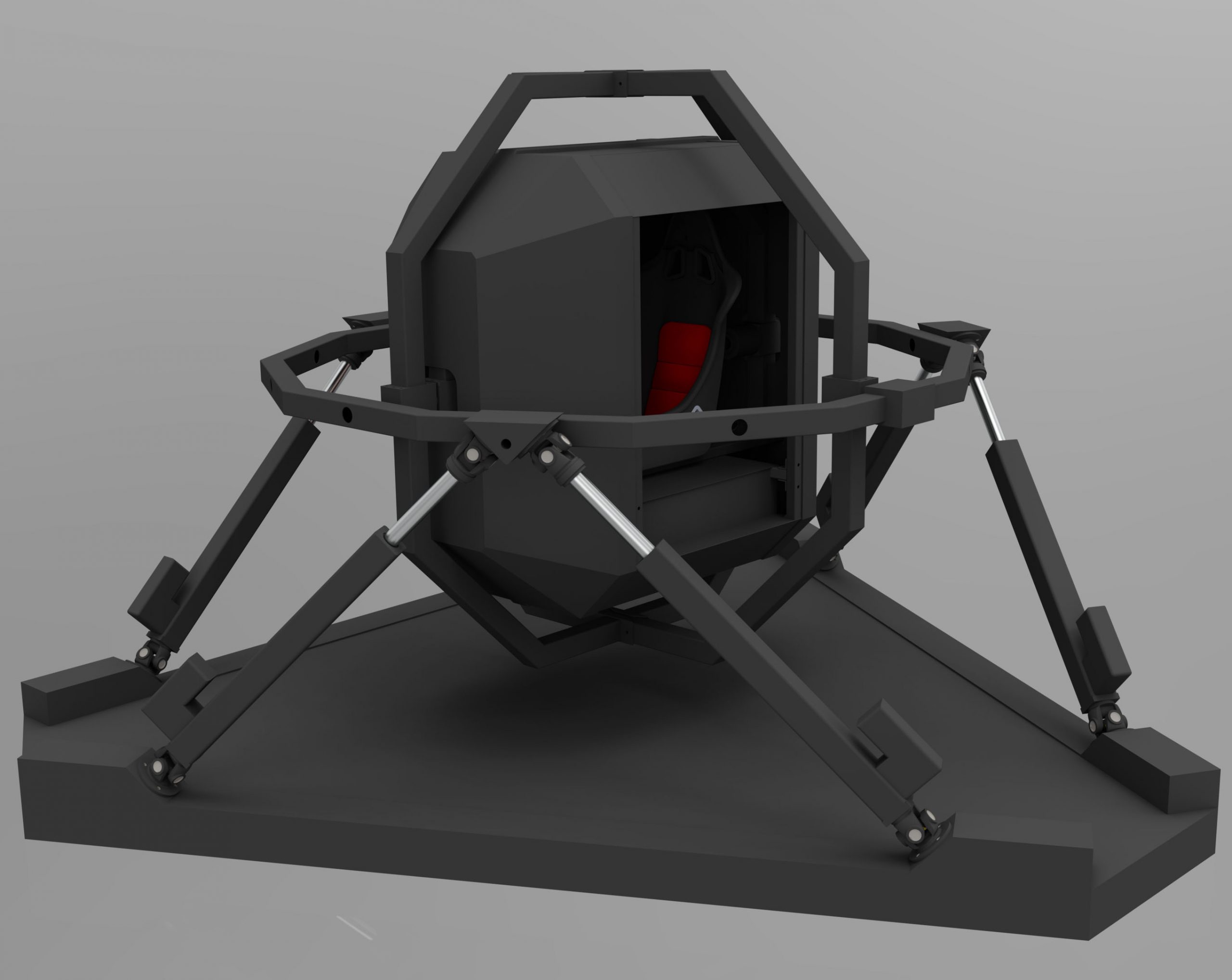

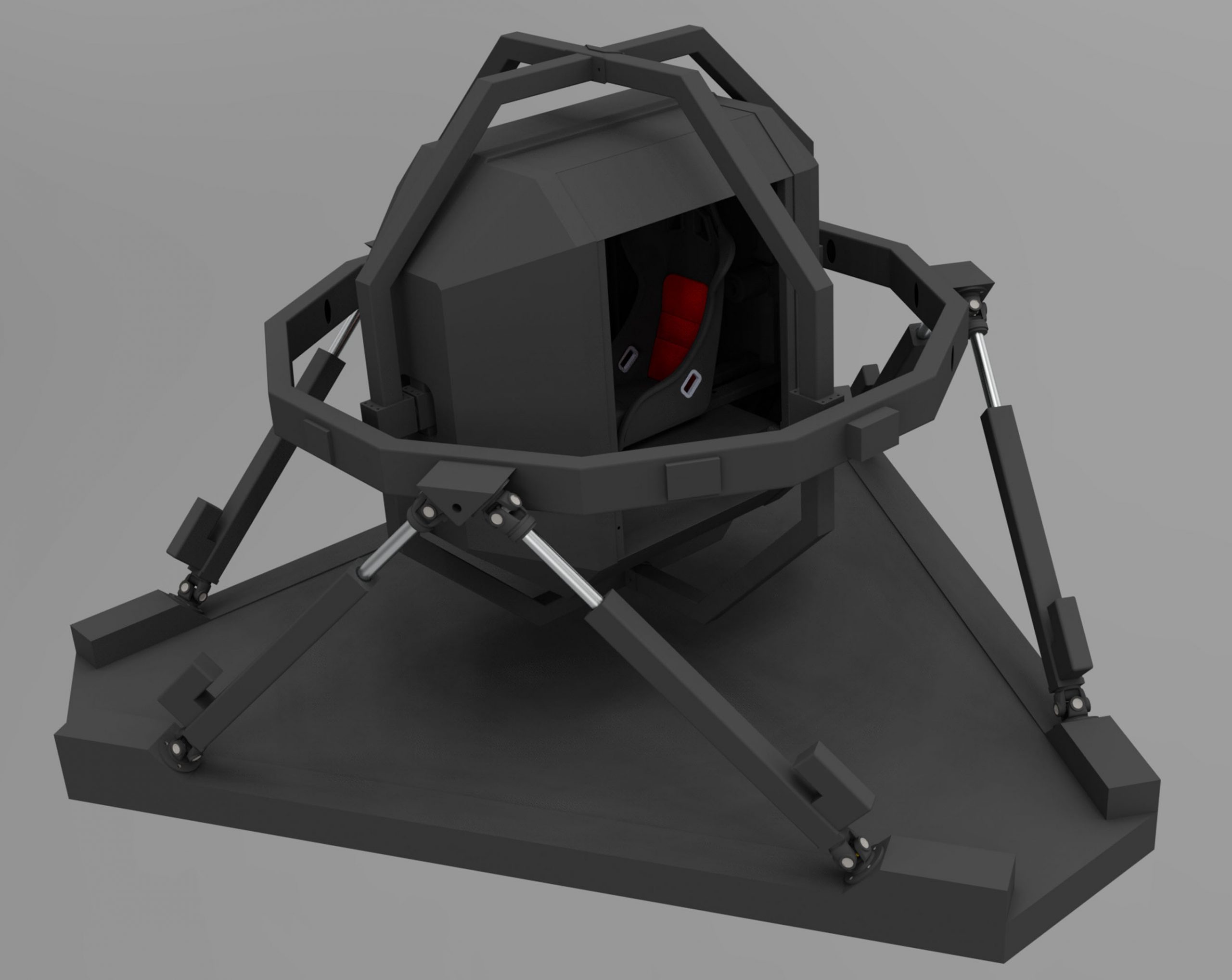

Simulator Detail

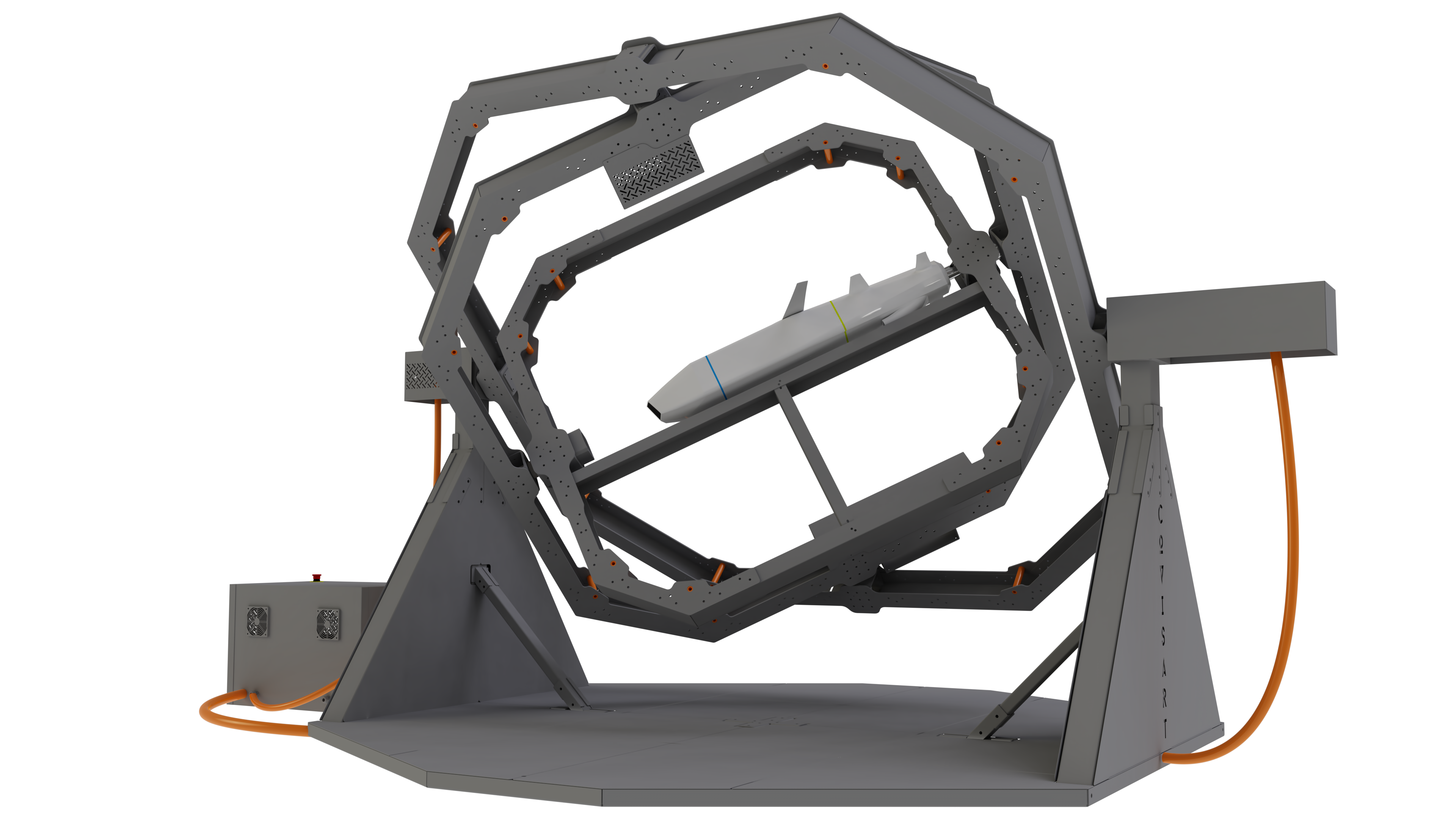

Motion Simulator CT-360/6+2 has 2 axis rotation and 6dof system. Rotation axis is based CT-360/2, speed turns on each two axis are 144 degree/s. This version is more advanced version of all simulators. You can find more detail about this system on second page. This version can simulate any vehicle(jet fighters, airplanes, helicopters, tanks and cars).

Vehicle simulator based on a motion system developed using virtual and augmented reality technologies. System supports multi axis motion systems. This simulator allows users to use the aircraft they want in a virtual environment. Using AR technology, user can interact with virtual cockpit. Unlimited rotation system provide most realistic flight experience.

Virtual Reality

The software developed by Covisart displays the interior of the vehicles in a stereoscopic way, allowing users to see the interior of the vehicle in 3D as in the real world.

With Virtual Reality Technology, it is able to simulate every environment and all kinds of vehicles.

Augmented Reality

The user interacts with the interactive parts in the vehicle created in a virtual environment using Augmented Reality technology. For example: While creating the cockpit of an F-35 fighter aircraft in virtual reality and displaying it to the user in 3D, user can interact with the buttons in the cockpit with AR.

Mechanical System

The motion system, which has unlimited rotation capability in 2 axes, applies the movements of the vehicle in simulation with 1ms communication speed to the user. Developed by taking gyroscope as an example, this machine supports not only 2 axes but also multiple axes.

Safety first of all!

Mechanical and software are tested and documented.

One of the most important points of the systems used in the motors and mechanical accents are designed with utmost safety in mind, and special protection software is taking all kinds of security measures.

High Speed Communication

Thanks to the high precision and fast data processing servo motors used in the mechanical parts, it achieves 1ms communication speed. If we consider the 5ms image refresh rate of the computer screens we use today, it is possible to realize that the simulator has a faster communication power than thought.

Major Development in Education

Providing one-to-one vehicle training with low cost, the New Generation Simulator now provides a very easy and reliable visual environment.

| General performance | |

|---|---|

| Payload (load on top of the platform) | 6000 Kg |

| Actuator stroke | 935 mm |

| lxx | 15000 Kgm² |

| lyy | 15000 Kgm² |

| lzz | 15000 Kgm² |

| Relative to COG of the payload) | |

| Settled height | 2.322 m |

| Distance of COG above topside platform |

1.044 mm |

Excursions

| Direction | Minimum | Maximum |

|---|---|---|

| Surge | – 0.806 m (-31.73 in) | 0.841 m (33.11 in) |

| Sway | – 0.751 m (-29.57 in) | 0.751 m (29.57 in) |

| Heave | – 0.536 m (-21.10 in) | 0.460 m (18.11 in) |

| Roll | – 360 deg | 360 deg |

| Pitch | – 360 deg | 360 deg |

| Yaw | – 28.7 deg | 28.7 deg |

Velocities

| Direction | Velocity | |

|---|---|---|

| Surge | +/- 0.80 m/s | +/- 31.50 in/s |

| Sway | +/- 0.75 m/s | +/- 29.53 in/s |

| Heave | +/- 0.60 m/s | +/- 23.62 in/s |

| Roll | +/- 180 deg/s | |

| Pitch | +/- 180 deg/s | |

| Yaw | +/- 180 deg/s | |

Accelerations

The above performance figures are with the starting position ‘neutral’ and with the design payload.

| Direction | Acceleration | Onset |

|---|---|---|

| Surge | +/- 6.000 m/s² (+/- 0.612 g) | +/- 3 g/s |

| Sway | +/- 6.000 m/s² (+/- 0.612 g) | +/- 3 g/s |

| Heave | +/- 6.300 /s² (+/- 0.642 g) | +/- 3 g/s |

| Roll | +/- 572 °/s² | +/- 300 °/s²/s |

| Pitch | +/- 572 °/s² | +/- 300 °/s²/s |

| Yaw | +/- 572 °/s² | +/- 300 °/s²/s |

Interfaces

- Host computer

-

- Ethernet connection

- Update rate up to 1000 Hz

- Foot-print: 5200 mm x 4500 mm

- Floor attachment: Bolted using floor anchors

Worldwide customer support:

- 24-hour service and maintenance support by Covisart’s global service organization